Serpecon Ltd

Introduction

Serpecon conveyors are based on a range of standard designs in various sizes to suit a variety of operating conditions. These designs can be configured, modified and adapted as required for each contract to produce a tailored and bespoke solution to suit the customer’s specific requirements.

With extensive experience in the conveying industry, the company is continually improving and developing new products. In addition to conveyors, Serpecon offers a number of other complimentary products and services to the industry.

The business has it’s own manufacturing facility, fully equipped and with an experienced workforce, enabling it to manufacture all of it’s products in house.

What we do for Serpecon Ltd

We provide a complete 2D CAD drawing, 3D CAD modeling and project engineering service for Serpecon Ltd. Assisting their in house engineering department we work on large and small projects and also help develop new products for the company. From a single component drawing, to a complete multi conveyor project, we produce layouts, arrangements, detail and assembly drawings. We also visit sites as necessary and deal directly with Serpecon’s suppliers and customers in a project engineering role.

Examples of some of our work

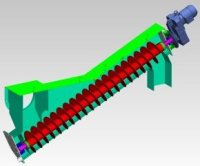

Grit screw conveyor

A small grit screw conveyor was required as a replacement for an old one (not supplied by Serpecon) at a waste water treatment works. The new conveyor had to be a direct replacement for the existing one which was installed in a launder trough. Drawings of the existing equipment weren’t available so dimensions had to be taken at site. We used the standard Serpecon design as a basis but adapted it by engineering a bespoke casing to match the launder trough dimensions.

Skip trolley

Serpecon had a standard design for a hand operated, rail mounted skip trolley. Although it functioned well, it was expensive to manufacture and adjusting the chain drive was difficult. Working with the Serpecon engineers, we modified the design to reduce cost and make it easier to build and set up. A full set of new manufacturing drawings were produced.

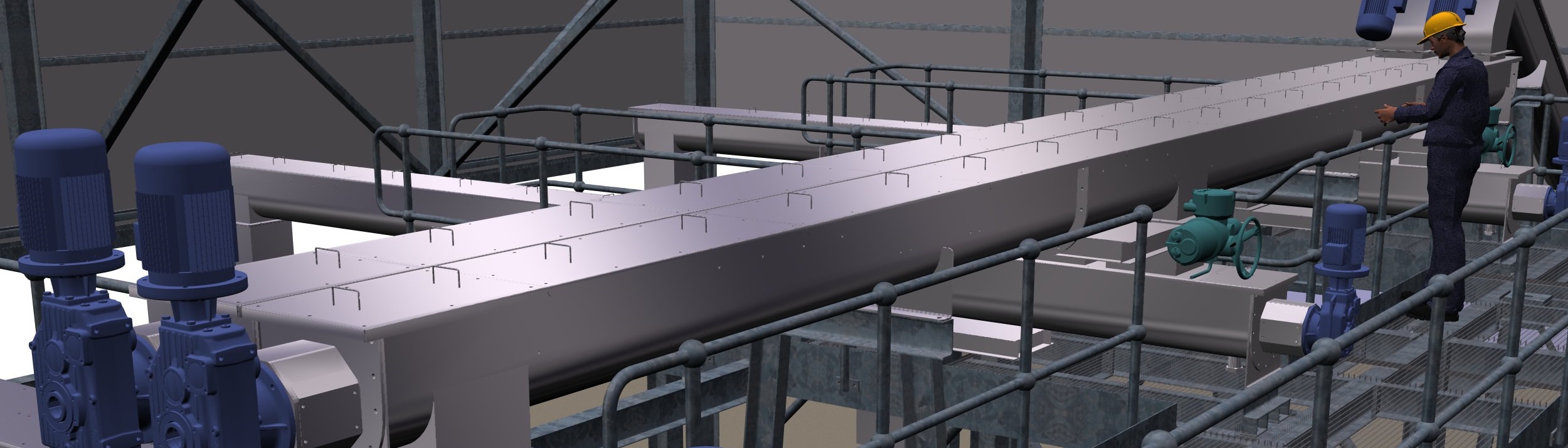

Dewatered sludge lorry loading system

We provided both a design and project engineering service for a multi conveyor project for a waste water treatment works. The scope of supply was 2 x inclined conveyors (15m long), 2 x distribution conveyors (11.5m long), 3 x lorry loading conveyors (8m long) and a support structure complete with stairs and platform.

At the tender stage we produced a 2D sales general arrangement drawing. When the project became a firm order, we produced a detailed 3D layout of the complete system. We then produced a set of manufacturing drawings for the three designs of centreless spiral conveyors.

The detail design of the support and platform was sub contracted to a specialist who also provided a set of design calculations. The design was based on our 3D layout and we worked closely with the designer to ensure the final design met Serpecon’s requirements.

In addition to producing drawings, we were involved with the procurement of various other pieces of equipment including the geared drive motors and the actuated slide valves. This included specifying, obtaining quotes and progress chasing.

We also had direct contact with Serpecon’s customer supplying arrangement drawings and answering various questions. They supplied us with the building drawing that their civil engineer had produced and we checked it and advised where they needed to make modifications to avoid clashes with the equipment.