ARN B.V.

Introduction

The ARN plant has two independent incinerators each generating steam for its own dedicated turbo-generator. Line 1 was installed in the 1980’s and generates approximately 8 MWe. In the mid 1990’s the capacity of the plant was increased significantly with the installation of line 2 providing an additional generating capacity of 19.8 MWe. At this time the line 1 installation was also modified and updated.

After a number of years service, the decision was made to replace the existing line 1 turbo-generator with a new machine. This posed a number of challenges for ARN. The new machinery was from a different manufacturer and some major modifications would be needed to both the foundations and the pipework installation. Down time of the plant also had to be kept to a minimum as obviously any time the plant wasn’t running would have an affect on the revenue it could generate. In addition, the capacity for storage of waste is limited and when the incinerator isn’t in operation the waste can build up to unmanageable levels.

A tight program was put together which was split into two phases to minimise downtime. Phase 1 covered the period from when the complete line 1 plant was shut down until the incineration plant was back in operation. During this phase steam and condensate pipework had to be modified and isolation valves installed. This would allow the incinerator to start up and ensure waste storage levels where kept to manageable levels. The existing turbo-generator also had to be dismantled and removed. This phase had to be carried out within a 3 week period. Phase 2 was for all other work including major modifications to the concrete foundation block, installation of the turbo-generator, pipework, instrumentation, steelwork and platforms. Testing and commissioning also had to be carried out within this period. This second phase was to be completed within 12 weeks giving a very tight total program time of just 15 weeks.

What we did for ARN B.V.

The role of Design & Draughting Solutions Ltd was to bring together the various items of equipment (from different suppliers) and integrate and package as a total installation within the existing plant.

From the start of the project it became apparent that good planning was required and it would be necessary to pre fabricate as much pipework as possible before the installation program started. To achieve this, a detailed 3D model would be needed to minimise the chance of pipework clashes with existing and new equipment.

Over a number of weeks, we built up a 3D CAD model of the new installation. This was produced from various sources of information including existing 2D (hand drawn) drawings from the original installation, drawings from the latter modifications, measurements taken at site and drawings of the new equipment to be installed. Existing and new pipework (steam, condensate, oil and water) was added to the model.

The 3D model was produced using CADWorx Plant Professional and each month the latest version was published as a Navisworks.nwd file. This model was presented at the monthly project meetings held by ARN allowing all of the project team to get a good understanding of how the finished plant would look. We also provided a free viewer to ARN which enabled any of their team to easily navigate around the published model by themselves as required.

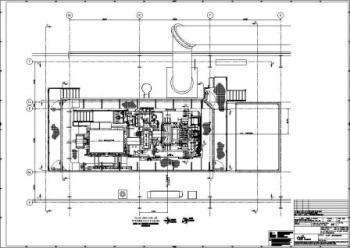

From the 3D model we generated a package of drawings including pipe arrangements, detailed pipe spool drawings, platform layouts, duct work modification drawings and plant arrangements. The total number of 2D drawings produced was approximately 50 A0 size sheets (arrangement drawings etc.), 135 A2 size sheets (pipe spool details) and 25 A3 size sheets (miscellaneous small details).

In addition we attended various meetings at site in The Netherlands including ARN’s regular project meetings and discussions with several subcontractors at the supplier selection stage. During the installation phase we provided a support service answering any questions as they arose.

The original plant was shut down and all necessary phase 1 work was carried out allowing the incineration plant to be re started after the 3 week period. The remainder of the work was then carried out and the new turbo-generator along with its associated plant was successfully installed, commissioned and handed over to ARN within the project timescale.